ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreBrochures

-

OSS Series Orbital Motion Side Seal Wrappers

The OSS Series Side Sealers are Texwrap’s highest speed continuous-motion sealers. The OSS design uses Texwrap’s patented orbital seal head that combines very fast, precise, servo controls with an elliptical motion of the sealing head. The orbital motion allows for extremely fast speeds by drastically reducing the seal head movement needed to make the seal. This feature combined with the 250 feet per minute conveyor speed makes it the fastest and most flexible wrapper of its kind.

![OSS Series Orbital Motion Side Seal Wrappers]()

-

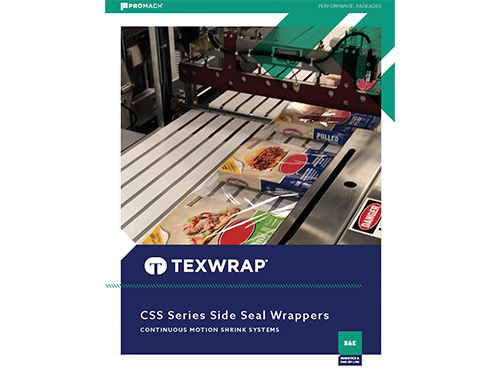

CSS Series Continuous Motion Side Seal Wrappers

The CSS Series is Texwrap’s continuous-motion side seal for applications demanding high throughput speeds and maximum package flexibility. The CSS Series “box-motion” style wrappers are some of Texwrap’s most popular machines due to their speed and versatility. The end seal moves horizontally with the product as the seal is made. When the seal is complete, the head raises and the carriage returns to make the next seal. The servo-driven seal gives the operator control of dwell time and seal pressure from the touchscreen.

![CSS Series Continuous Motion Side Seal Wrappers]()

-

ISS Series Intermittent Side Seal Wrappers

The ISS Series Intermittent Motion Side Sealer are Texwrap’s offering for applications requiring the wrapping of products at moderate speed, where product length or height exceeds the capacity of an L-sealer. Texwrap’s ISS Series machines are flexible enough to wrap anything from a deck of cards to a bundle of wood flooring. With film/conveyor speeds of 100 feet per minute, the ISS has plenty of speed to handle a variety of applications.

![ISS Series Intermittent Side Seal Wrappers]()

-

OVS Series Orbital Motion Vertical Wrappers

The Texwrap OVS Series Vertical Seal Systems are ideal for end-of-fillingline shrink packaging. Now products such as bottles, cans and jars can be wrapped while in the vertical position. The OVS Series machines use a full top or bottom trim seal instead of a lap seal to securely enclose the product. In addition to providing an outstanding seal, this eliminates the unsightly seam across the side panel of the package common with other machines.

![OVS Series Orbital Motion Vertical Wrappers]()

-

BVS Series Box Motion Vertical Wrappers

The BVS Series machines take the dual-axis servo CSS horizontal wrappers technology and applies it to wrap products in the upright position. The BVS Vertical Sealers are ideally suited to multipacks or variety packs of bottles, cans, jars, or canisters that exit upstream equipment in a vertical position, using either a top or bottom trim seal. Unlike side seal systems, the labor and expense of laying vertical product down for wrapping is eliminated.

![BVS Series Box Motion Vertical Wrappers]()

-

TLS Series L-Seal Wrappers

Robust, compact, and versatile, the TLS Series sets the standard for affordable L-Seal systems. Texwrap’s TLS Series L-Sealers simultaneously make the end and side seal of one package, as well as the front seal of the trailing package. The seal is made by feeding product into the centerfold film with photo-eyes detecting the leading and trailing edge of the product. L-Sealers fit applications where speeds are slow to moderate or where space is limited, and are affordable, versatile wrappers within a certain range of product sizes.

![TLS Series L-Seal Wrappers]()

-

EPS Series e-Commerce Solutions

Flexible, high output e-Commerce shrink wrapping and bagging systems. The e-commerce industry is evolving faster than ever. Businesses that want to harness the power of supply chains need confidence in their ability to deliver the right products to the right customer. Factors to consider range from customer experience and damage reduction to packaging performance and operational throughput.

![EPS Series e-Commerce Solutions]()

-

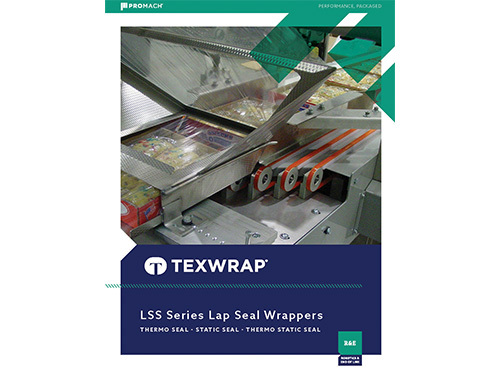

LSS Series Lap Seal Wrappers

LSS Lap sealers are most popular in applications which call for long runs of same-sized products. Texwrap LSS Series can accommodate thermo seal lap seal, static seal lap seal and a thermo static lap seal either as operator options within the same machine or dedicated to one type depending on the application. Lap sealers are most popular in applications which call for long runs of constant-sized products because each product requires an individually sized plow and a specific width of film to be stocked.

![LSS Series Lap Seal Wrappers]()

-

Tekkra 100 & 1000 Series Inline Bundlers

The Tekkra inline shrink bundlers or wrappers are an ideal solution for wrapping trays of product in clear film. Both the Tekkra 100 and 1000 series product use dual rolls of film to envelope the product in trays which is passed through a tunnel to produce a product which is shrink bundled or wrapped with a bullseye at each end.

![Tekkra 100 & 1000 Series Inline Bundlers]()

-

Beverage & Canning Solutions

Texwrap’s shrink packaging expertise spans decades - working with large and small operations throughout the food and beverage industries. Ranging from regional producers needing medium speed capability, to the largest national brands requiring extreme high-speed custom solutions.

![Beverage & Canning Solutions]()

-

Contract Packaging Solutions Industry Brochure

Texwrap recognizes the vital role contract packaging serves in today’s manufacturing. Whether the requirement is unitization of bulk packaged products, short term promotional products, or new product test runs, Texwrap shrink packaging equipment is uniquely suited to meet those demands. Tailored for contract packaging requirements, Texwrap shrink wrappers are robust, durable solutions, with a high degree of flexibility and ease of changeover.

![Contract Packaging Solutions Industry Brochure]()

-

Household & Cleaning Products Shrink Wrap Systems

Texwrap has valuable experience helping household cleaning product suppliers bring shrink wrapped solutions to market. From disinfectant wipes and hand sanitizers, to floor cleaners and soaps, Texwrap has collated and shrink wrapped canisters, bottles, tubs, boxes and jugs. Each product wrapped in clear or printed film with pristine retail-ready presentation and secure containment.

![Household & Cleaning Products Shrink Wrap Systems]()

-

Nutraceutical Shrink Wrap Systems

From nutraceuticals, such as sports or energy drinks to OTC, immune boosters and dietary supplements, Texwrap has a complete portfolio of shrink wrap solutions to meet our customer’s needs. Texwrap equipment has a reputation for producing high quality multipacks of jars, cans, cartons or bottles. With the best print registration and tunnel controls on the market, Texwrap equipment produces esthetically appealing printed or unprinted shrink film packages that satisfy even the most discerning eyes.

![Nutraceutical Shrink Wrap Systems]()

-

Pizza Wrapping Solutions

With U.S. frozen pizza sales topping 5 billion dollars in 2019, more bakers in the U.S. today depend on Texwrap equipment to wrap their pizzas than any other packaging equipment company in the industry. Texwrap’s pizza packaging expertise spans decades - working with pizza operations large and small. Ranging from regional producers needing medium speed capability, to the largest national brands requiring extreme high-speed custom solutions. Regardless of the speed required, Texwrap’s heavy duty and reliable pizza handling and shrink packaging systems can improve efficiency, reduce labor costs, increase production and better utilize your operating space. The quality and durability of Texwrap equipment provides the lowest total cost of ownership available in the market today.

![Pizza Wrapping Solutions]()

-

Frozen Pizza Packaging Solutions

ProMach product brands Texwrap, Brenton & Orion are even better together, offering fully automatic Frozen Pizza Packaging Solutions to help customers reduce labor, while increasing efficiency and output.

![Frozen Pizza Packaging Solutions]()

-

Wine & Spirits Shrink Wrapping & Bundling Experts

No matter how you go to market Texwrap and Tekkra shrink wrappers and shrink bundlers provide solutions for the wine & spirits industries that cover the gamut of unsupported and supported multipacks. From mini's to full size bottles, cartons, and cans, Texwrap & Tekkra equipment bring it all together - retailready presentation, secure containment, and unmatched equipment reliability. Plus, the quality and durability of our equipment provides the lowest total cost of ownership available in the market today.

![Wine & Spirits Shrink Wrapping & Bundling Experts]()

-

Texwrap Changeover Reduction Options

Options to reduce downtime due to changeover

![Texwrap Changeover Reduction Options]()

-

The Shrink Wrapper Next Door: How Texwrap Enhanced Growth for The Empac Group

![The Shrink Wrapper Next Door: How Texwrap Enhanced Growth for The Empac Group]()

-

Kayat SRX Series Single Roll Bundlers

![Kayat SRX Series Single Roll Bundlers]()

-

Pet Care Solutions Industry Brochure

As the Pet Care industry continues to grow and change, the call for additional automation continues to be an important element to its growth. Texwrap’s solutions have included wrapping raw hides to multipacking pet treats to tray shrink bundling applications.

![Pet Care Solutions Industry Brochure]()